CHEMICHAL RECYCLING

Innovative recycling means shaping the future

We solve the problem of plastic waste

Plastics are exceptionally versatile materials that play an integral role in virtually all aspects of modern life and have become indispensable to contemporary society. A healthy, modern lifestyle is almost inconceivable without plastic products—and in many instances, simply impossible. However, plastics are still produced almost entirely from fossil-based raw materials such as crude oil and natural gas. These finite raw materials are becoming increasingly scarce; their extraction and processing place a heavy burden on the environment and the climate.

Plastics last (almost) forever!

The very properties that make plastic products so valuable in use become problematic once they reach the end of their lifecycle and are discarded as waste. In Germany, the collection and sorting of plastic waste remains a major challenge—and globally, discarded plastic remains a key driver of increasing environmental contamination. Unfortunately, a large proportion of this waste is incinerated, leading to significant CO2 emissions and accelerating climate change.

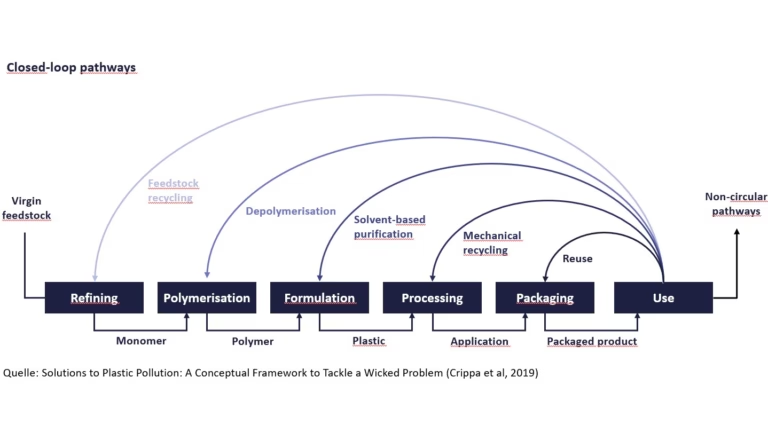

To mitigate the environmental impact of plastic waste without sacrificing the many benefits of plastic products, we must transition to a circular economy. While mechanical recycling plays an important role, it has its limitations—this is where carboliq goes one step further: Our chemical recycling process recovers valuable raw materials that can be reused in sustainable, high-quality applications.

Recycling matters—both mechanical and chemical

If we want to avoid environmental damage without giving up the benefits of plastics, we need to establish closed-loop recycling systems for these materials.

Unfortunately, recycled plastics can seldom be reused for their original purpose. Instead, plastic waste is mechanically sorted, cleaned, and reprocessed for alternative applications. Because these are generally of lower quality or value, the process is known as “downcycling”.

Plastics are products of the chemical industry, created by combining hydrocarbons with other elements to give them unique properties.

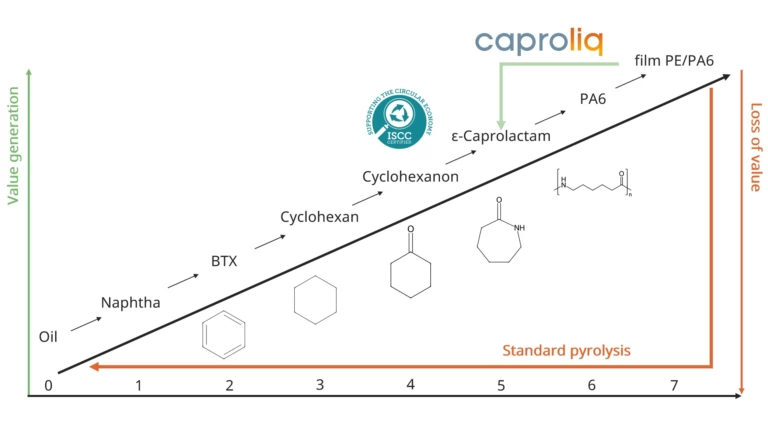

But what happens when a plastic product can no longer serve its purpose – and downcycling is no longer a viable option? In this case, the plastic must be broken down into its original chemical building blocks. These components can then be reused to produce high-quality products—a process known as chemical recycling.

Chemical recycling enables the recovery and reuse of hydrocarbons, effectively closing the material loop for plastics. This helps conserve valuable resources while reducing their environmental impact.

The carboliq process—the key to a sustainable circular economy

The carboliq process offers a viable solution to the problem of plastic waste.

Our unique recycling technology breaks down plastics into their original chemical components and returns them to the material loop—without incineration, and with the added benefit of conserving valuable resources. The process is not only efficient but also economically viable, even on a smaller scale. carboliq is especially effective for mixed and contaminated post-consumer plastics, helping to close the material loop while making a valuable contribution to environmental and climate protection.

Together, we can build sustainable solutions for the future. carboliq helps you take a meaningful step toward a circular economy.

Got questions about recycling?

We’ve got the answers!

Press and news

Visit our Press page for the latest developments at carboliq, including updates on exciting projects and recent presentations.